Product Team

--------------------------------------------

--------------------------------------------

1 UI Designer

1 UX Designers

1 Industrial Designer

-------------------------------------------

Project duration: 2 years

"Single-use mixers have significantly sped up the process of mixing ingredients in pharmaceutical production, reducing the time to market for vital drugs and vaccines."

Overview

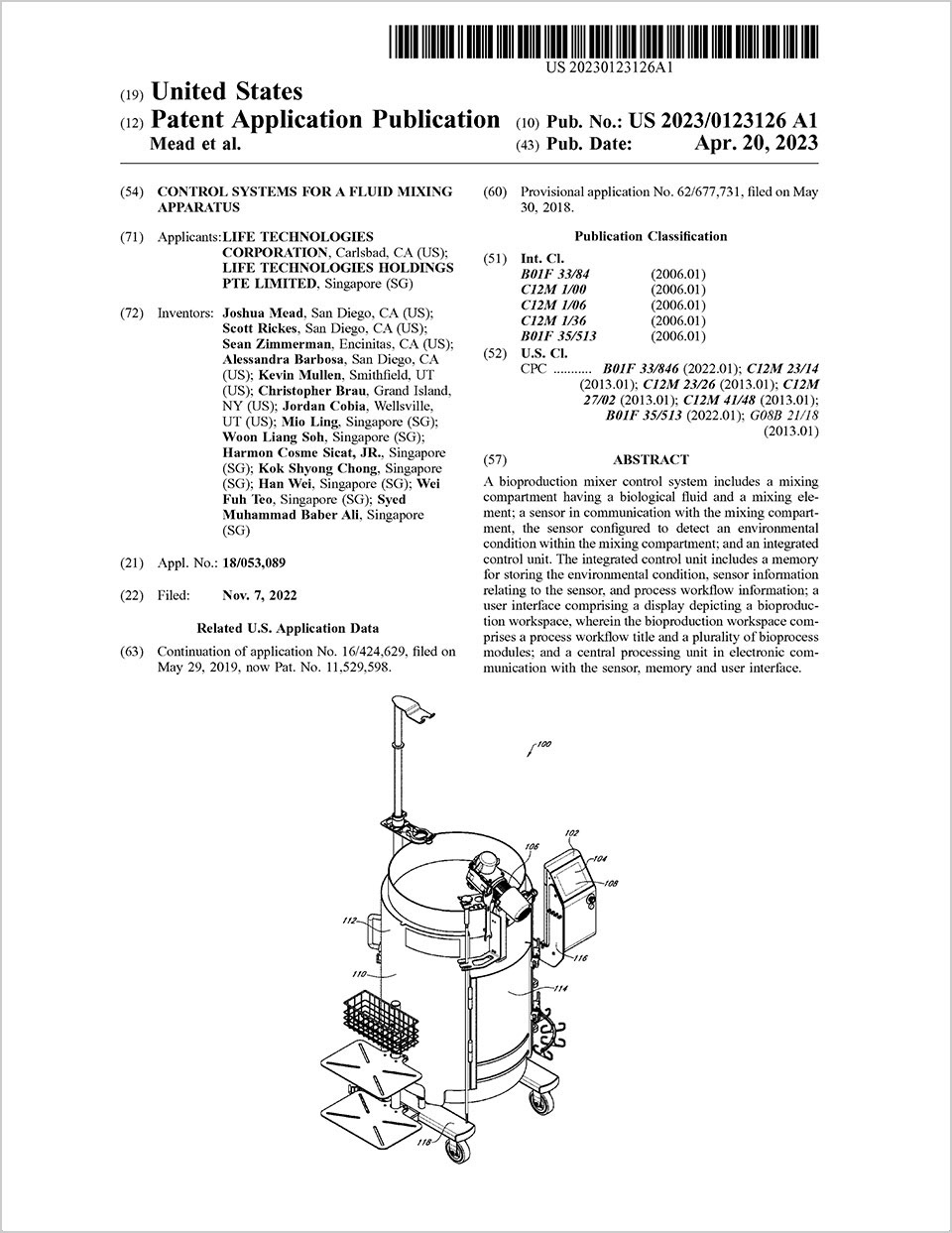

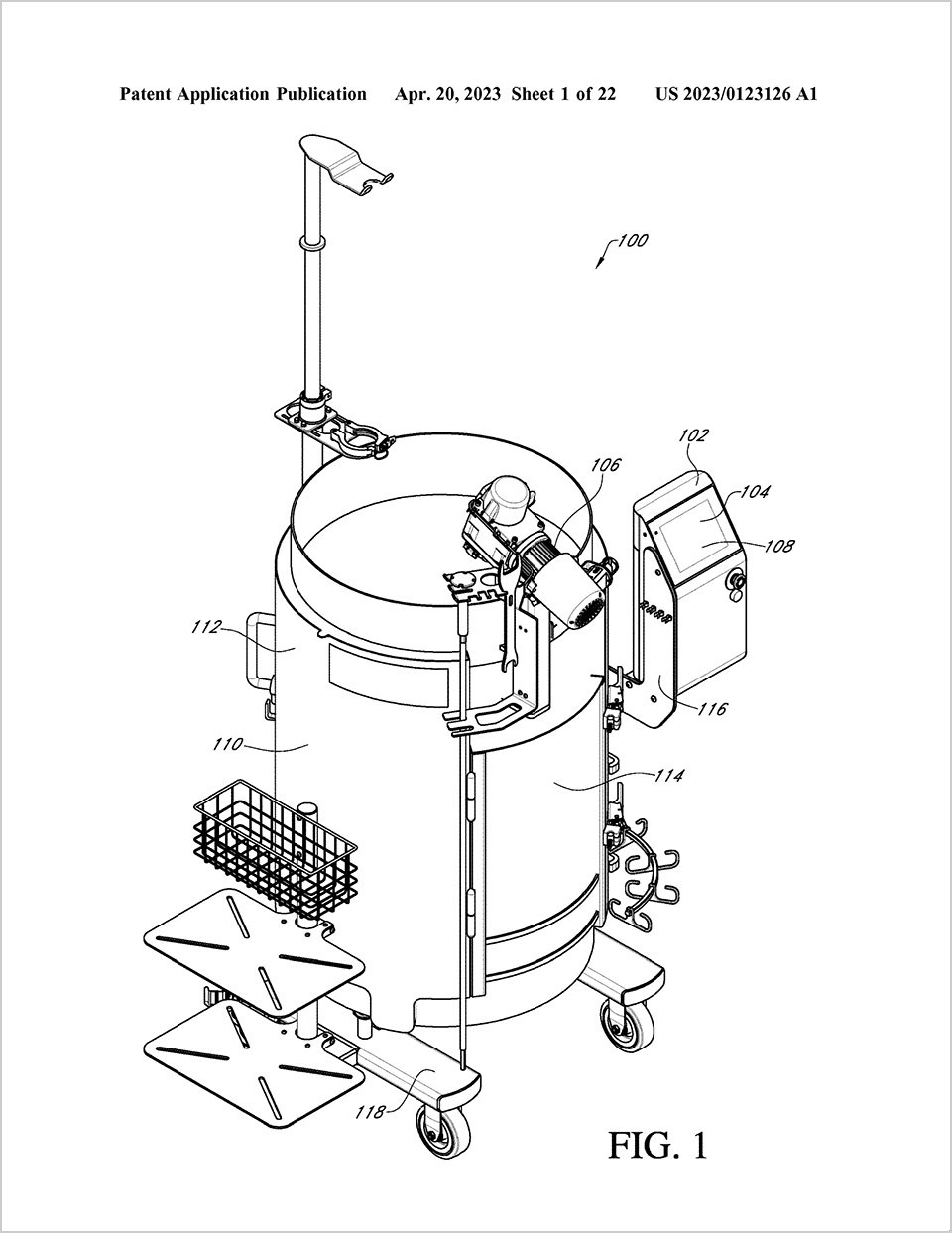

Biologics manufacturing has seen many new developments in recent years. The industry is moving away from processing systems based on stainless steel (with cleaning and validation requirements) to single-use systems (sterilized, disposable plastics).

The last 20 years have seen a rapid growth in the development of therapeutic molecules and biologics. In addition to the expansion of mAb production, the industrialization of gene therapies and the growth of new vaccine platforms also share many of the same process challenges. In order to translate these molecules into clinical and commercial success, manufacturers are looking to increase production efficiency, lower production costs and accelerate the development of manufacturing processes.

The Challenge

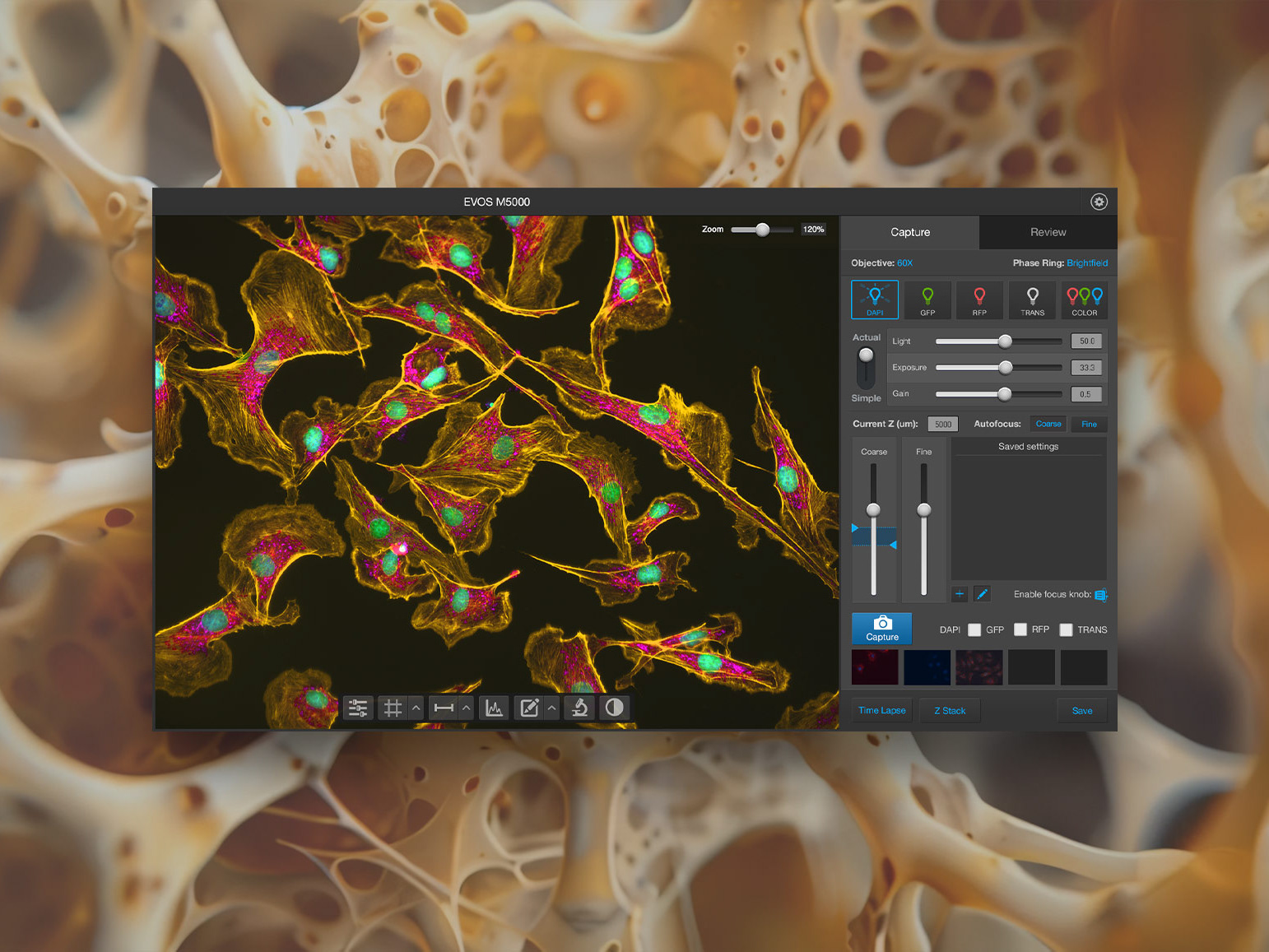

I worked with a UX designer to transfer our design philosophy to a new business segment - Thermo Scientific. This would also be the first time a module containing a touch screen interface would be used on individual mixers. From a UX perspective, we needed to learn the work flows of a DeltaV platform, usually used on a larger computer located in the lab, and translate those ideas into our "mobile first" philosophy. It was also the UX designer's first, full design project to tackle, so he needed some guidance. I was critical to that accomplishment.

From a visual design standpoint, I needed to create a whole new set of components that matched the overall look and feel of other Thermo Scientific products. The translation turned out pretty nice.

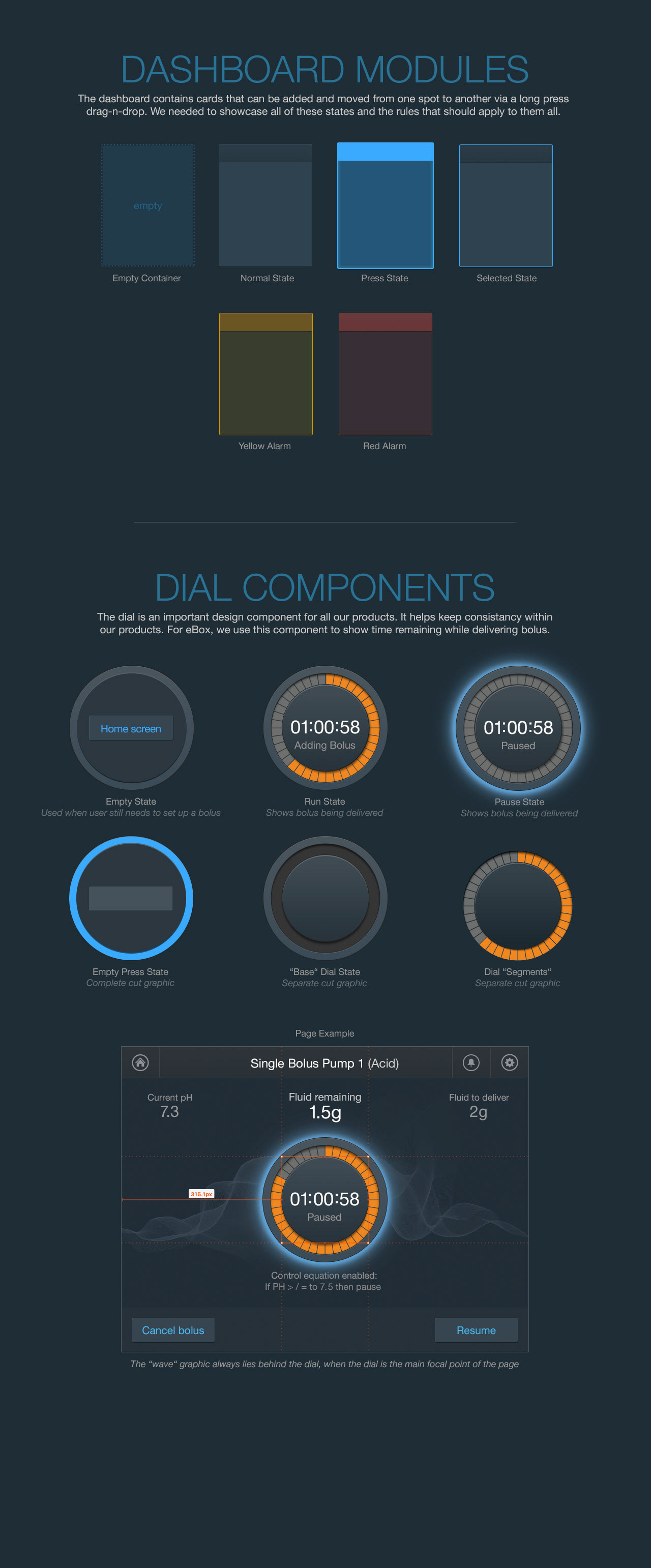

With multiple modules on this mixer, we needed a screen to display the status of each element. Users begin by "building" each element, assigning status inputs to define its parameters. Once all inputs are set, the element becomes a functional module. And, when all modules are complete, the mixer becomes fully operational.

During operation, the dashboard is the instrument's most critical feature. Scientists must continuously monitor each module to ensure it remains locked at its set point. If an issue arises, they need instant alerts and a clear, intuitive way to resolve it quickly.

Filtering and Acknowledging Alarms

Here’s an example of the initial wireframes for the alarm system, followed by the final visual designs. Alarms are critical in this line of work—pH and conductivity levels must remain within specific parameters tailored to each mixture. If temperature or pH levels stray from these set points, the entire batch could be compromised. Whenever an alarm is triggered, the user must acknowledge it and confirm that corrective action has been taken.

Example of Adding a Bolus

Here is an example of what it looks like adding a bolus. I was able to incorporate our iconic dial. Adding components like this help make the product fit more with the other brands at Thermo. Plus, it's important for flows to feel similar from instrument to instrument. That sense of familiarity is important, as our users usually have more than 1 of our instruments on hand.

Style Guides Created

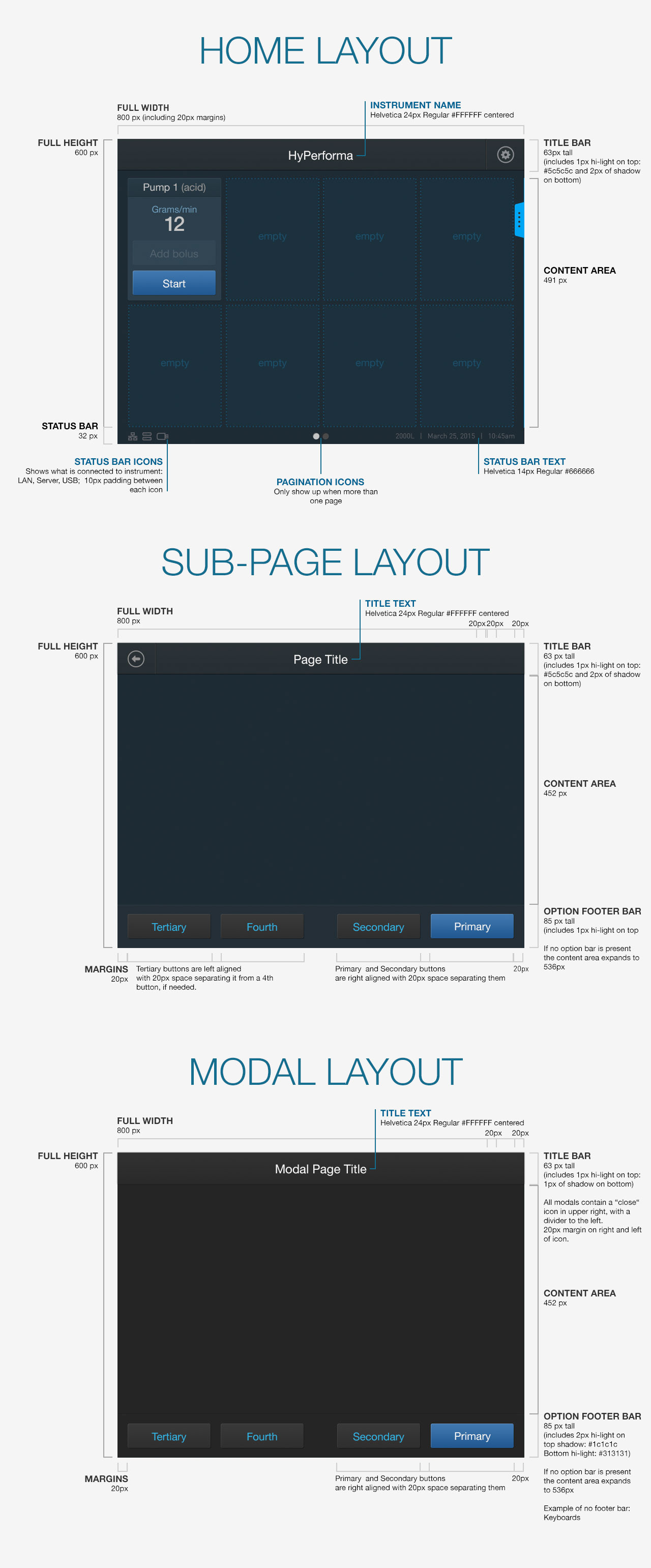

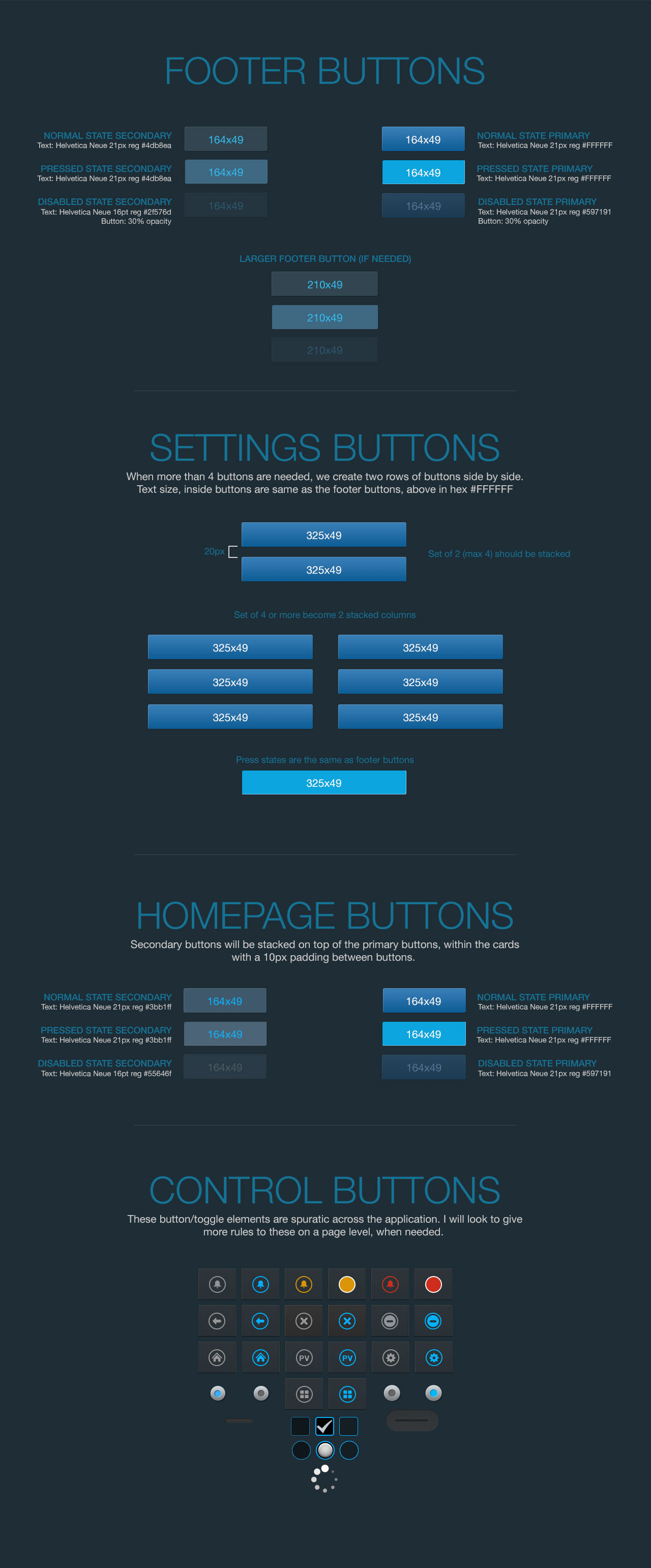

Here is the finalized style guide I created to support the team, providing clear direction for engineers as they build the final product.